Various biotic and abiotic stresses pose a threat to peanut production. Among these stresses, the soilborne fungi Aspergillus flavus and A. parasiticus contaminate peanut seeds with aflatoxins rendering them unsuitable as food. In this communication, US peanut producers learn about recommendations for reconditioning and disposing of aflatoxin-contaminated peanuts.

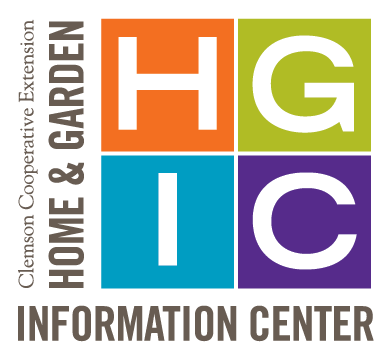

Peanuts are produced mainly in the southern United States, with Georgia, Florida, and Alabama being the lead producers (figure 1).1 Peanuts (Arachis hypogaea) are used for various purposes, including oil extraction, snack, candy, and peanut butter production (figure 1).2 The use of peanuts for butter production has increased significantly over the past two decades (figure 1). Various biotic and abiotic stresses pose a threat to peanut production. Among various stresses, the soilborne fungi Aspergillus flavus and A. parasiticus are among the major causes of yield reduction and quality deterioration leading to reduced economic returns and produce wastage. These notorious plant pathogens infect and contaminate peanut seeds with aflatoxins. These infections could occur in the field and during storage. For more information on types of aflatoxins, their flow in the food chain, and management, readers are referred to the “Management of Aflatoxins in Peanut” publication (https://bit.ly/36lYpwU).3

Figure 1. Upper left: US peanut production in 2019 (lbs/acre). Different colors denote differences in the production level (darker shades represent higher production levels). Upper right: The graph illustrates the area planted to peanuts (in acres) in different states during 2019. Notice the production level corresponded with the planted acres, but not in all cases. Lower: Peanut uses in the United States between 1980 and 2019 (in a million pounds). Peanuts are used mainly for peanut butter production, for which consumption has significantly increased over the past two decades [Data Source: The United States Department of Agriculture (USDA)]. Image credit: Tariq Alam, Clemson University.

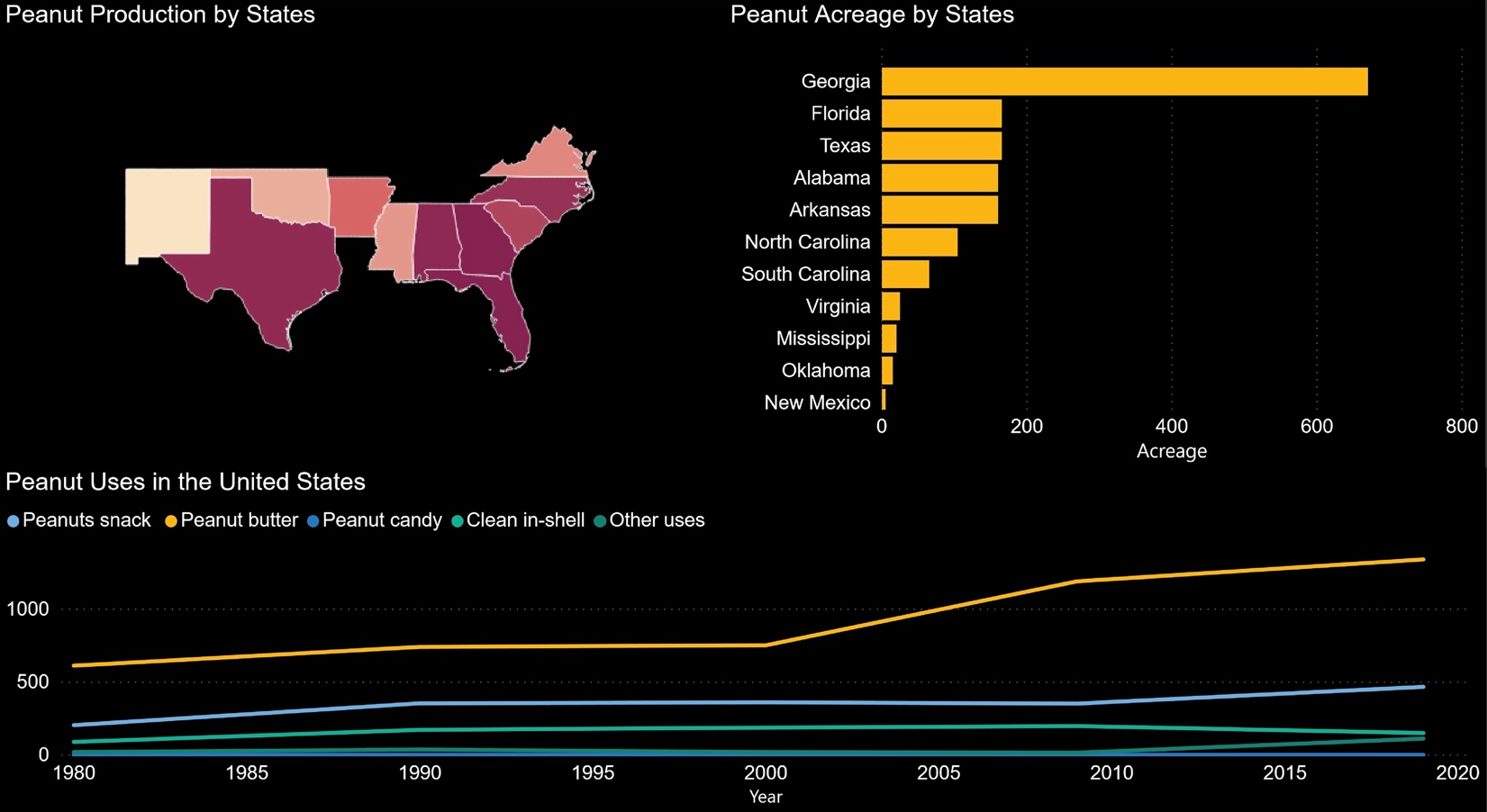

Figure 2. Transect showing fields from which soil samples were collected and exampled for Aspergillus species (i). Open dots represent fields planted in peanuts (total = 82), and filled dots represent fields planted in corn, cotton, or soybeans (total = 84). Major peanut-growing regions are indicated: A, western Texas; B, central Texas; C, Georgia/Alabama; and D, Virginia/North Carolina. Incidence of A. flavus (ii) and A. parasiticus (iii) (as a percentage of filamentous fungi) in soil from fields along a transect. Figure modified from Horn and Dorner.4

Policy for Detoxification/Reconditioning of Peanut Aflatoxin

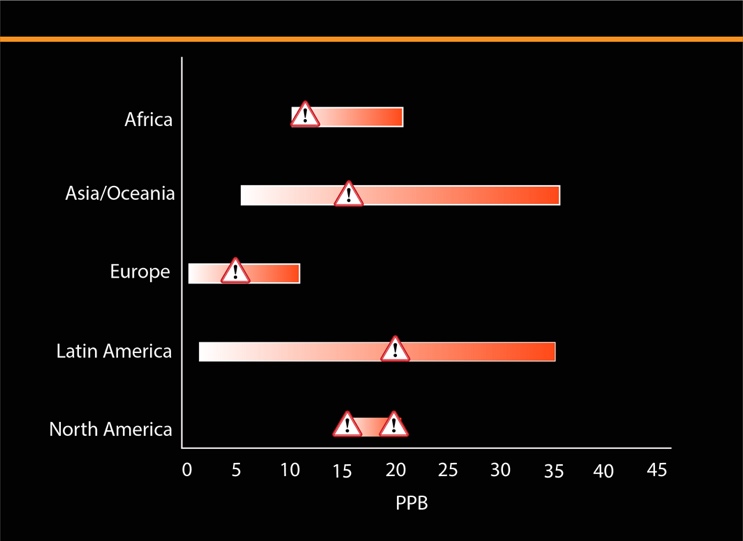

Figure 3. Aflatoxin (cumulative) limits of peanuts around the world. Bars = ranges and Δ = typical maximum levels of total aflatoxins (modified from Gong et al.11).

Currently, no policies exist for the detoxification of aflatoxins in peanuts. However, processes like blanching can reduce contamination levels, as discussed below. The peanut aflatoxin content exceeding the allowed level of 20 ppb must be reported to the US Food and Drug Administration (FDA), which regulates aflatoxin in both food and feed under the Federal Food Drug and Cosmetic Act (FFDCA).8 Although the FDA observed action limit for aflatoxins (cumulative) is 20 ppb, in practice, the industry generally follows a strict, self-imposed limit of 15 ppb total aflatoxins for peanuts.9 Also, the peanut aflatoxin level (cumulative) observed in different countries varies significantly10,11 (figure 3), which affects the trade.

Peanut Aflatoxin Reconditioning Procedure

The United States Department of Agriculture (USDA) will allow the reconditioning of aflatoxin-contaminated peanut under the following conditions14 (as of June 2021):

- Peanut lots that fail to qualify the certification for human use can be disposed of for livestock consumption (recommendations provided in the next section in table 2). The aflatoxin-contaminated lots should be identified by red tags, and the shipping paper of contaminated lots should state, “The peanuts covered by this bill of lading (or invoice, etc.) are not to be used for human consumption.”

- Contaminated lots that fail the established quality standards (table 1) may be used for milling. However, if lots satisfy the established quality standards (table 1) after milling, those could be used for human consumption under the required aflatoxin certification.

- Shelled peanuts that fail the quality standard (table 1) may be blanched. If the peanut lots satisfy the quality standards after blanching (table 1), the lots may be used for human consumption under the required aflatoxin certificates. Damaged kernels and minor defects are exempt from fall-through standards (table 1) before and after blanching.

- A valid grade inspection certificate should identify lots of shelled peanuts transported for milling or blanching. Milling and blanching should be performed at the USDA-approved centers.

- Peanuts received after milling or blanching should be identified by red tags and returned to the handler for disposal under the USDA-approved crushers.

- USDA has the right to reinspect domestic or imported peanuts if they suspect the peanuts to be contaminated, damaged, or deteriorated under the storage conditions. In such a scenario, USDA can reject the then-effective inspection certificate, and the owner may be required to request re-inspection to know if peanuts may or may not be used for human consumption.

- The peanuts owner should bear the cost of the inspection, transportation, sampling, chemical analysis, identification, milling, blanching, certification, and peanut disposition.

Table 1. Minimum quality standards of shelled peanuts for human consumptions.12

| Excluding Lots of “Splits” | |||||||

| Type and Grade Category | Moisture (%) | Unshelled Peanuts, Damaged Kernels, and Minor Defects (%) | Foreign Materials (%) | Total Fall Through Sound Whole Kernels and/or Sound Split and Broken Kernels | |||

| Runner | 9.0 | 3.50 | 0.20 | 6.0%; 17/64 round screen | |||

| Virginia (except No. 2) | 9.0 | 3.50 | 0.20 | 6.0%; 17/64 round screen | |||

| No. 2 Virginia | 9.0 | 3.50 | 0.20 | 6.0%; 17/64 round screen | |||

| Spanish and Valencia | 9.0 | 3.50 | 0.20 | 6.0%; 16/64 round screen | |||

| Runner with splits (not more than 15% sound splits) | 9.0 | 3.50 | 0.20 | 6.0%; 17/64 round screen | |||

| Virginia with splits (not more than 15% sound splits) | 9.0 | 3.50 | 0.20 | 6.0%; 17/64 round screen | |||

| Spanish and Valencia with splits (not more than 15% sound splits) | 9.0 | 3.50 | 0.20 | 6.0%; 16/64 round screen | |||

| Lots of “splits” | |||||||

| Type and Grade Category | Moisture (%) | Unshelled Peanuts, Damaged Kernels, and Minor Defects (%) | Foreign Materials (%) | Total Fall Through Sound Whole Kernels and/or Sound Split and Broken Kernels | |||

| Runner (not less than 90% splits) | 9.0 | 3.50 | 0.20 | 6.0%; 17/64 round screen | |||

| Virginia (not less than 90% splits) | 9.0 | 3.50 | 0.20 | 6.0%; 17/64 round screen | |||

| Spanish and Valencia (not less than 90% splits) | 9.0 | 3.50 | 0.20 | 6.0%; 16/64 round screen | |||

Source: FR 57140; Electronic Code of Federal Regulations; 2021

Note: The FDA observed action limit for human consumption is 20 ppb. However, in practice, the industry generally follows a stricter limit of 15 ppb total aflatoxins for peanuts.9

Disposition of Aflatoxin Contaminated Peanuts

After receiving the peanut lot’s screening resulting from the reconditioning process, the peanut grain industry must strictly follow the FDA’s aflatoxin disposition policy. Generally, contaminated grains disposition should occur as follows:

- Peanut screening may be used for animal feed only if the aflatoxin amount meets the FDA-imposed feed guidance (table 2). Once appropriated to be screened for feed use, the screening should not flow back into the human food channel in any manner.13

- Reconditioned peanut that contains less than 20 ppb aflatoxin may be handled without any restriction and regulations. However, when the reconditioning request result again indicates that peanuts exceed the actionable level of 20 ppb aflatoxin, proper disposition should be based on the FDA policy.13

For more information regarding the disposition of aflatoxin, contact your local FDA office for specific questions and concerns.

Table 2. FDA aflatoxins limits in animal food.14

Source: FDA Sec. 683.100 Action levels for aflatoxins in animal food compliance policy guide. 2019

*For example, ducks and chicken less than 8 weeks old, turkey less than 12 weeks old, pigs, sheep and goats less than 4 months old, equine and cattle less than 6 months old.

Acknowledgments

This work was supported by the National Peanut Board, SC Peanut Board, and NIFA Hatch/Multi-state grant (S009).

References Cited

- National Peanut Board. Atlanta (GA): National Peanut Board; 2021 [accessed 2021 Jun 22]. https://www.nationalpeanutboard.org/peanut-info/peanut-country-usa.htm.

- Whitley’s Peanut Factory. Fun facts. Williamsburg (VA): Whitley’s Peanut Factory; 2021 [accessed 2021 Jun 22]. https://www.whitleyspeanut.com/funfacts.

- Alam T, Anco DJ, Rustgi S. Management of aflatoxins in peanut. Clemson (SC): Clemson Cooperative Extension, Land-Grant Press by Clemson Extension; 2020. LGP 1073. doi:10.34068/report7.

- Horn BW, Dorner JW. Soil populations of Aspergillus species from section Flavi along a transect through peanut-growing region of the United States. Mycologia. 2009;90:767–776. doi:10.1080/00275514.1998.12026969.

- Gilbert MK, Mack BM, Moore GG, Downey DL, Lebar MD, Joardar V, Losada L, Yu JJ, Nierman WC, Bhatnagar D. Whole genome comparison of Aspergillus flavus L-morphotype strain NRRL 3357 (type) and S-morphotype strain AF70. PLoS ONE. 2018;13:e0199169. doi:10.1371/journal.pone.0199169.

- Lewis MH, Carbone I, Luis JM, Payne GA, Bowen KL, Hagan AK, Kemerait R, Heiniger R, Ojiambo PS. Biocontrol strains differentially shift the genetic dtructure of indigenous soil populations of Aspergillus flavus. 2019; Frontiers in Microbiology. 10:1738. doi:10.3389/fmicb.2019.01738.

- Amaike S, Keller NP. Aspergillus flavus. 2011; Annual Review of Phytopathology 49:107–133. doi:10.1146/annurev-phyto-072910-095221.

- Dohlman E. Mycotoxin hazards and regulations: impacts on food and animal feed crop trade, international trade and food safety: Economic theory and case studies, J Buzby (ed.), Agricultural Economic Report 828. 2003; USDA, ERS.

- Food Safety News. U.S. lacks sufficient aflatoxin checks on peanuts destined for Europe. Seattle (WA): Marler Clark; 2020 [accessed 2021 May 11]. https://www.foodsafetynews.com/?s=U.S.+lacks+sufficient+aflatoxin+checks+on+peanuts+destined+for+Europe.

- Van Egmond HP, Jonker MA. Worldwide regulations for mycotoxins in food and feed in 2003. Rome (Italy): Food Quality and Standards Service (ESNS), Food and Agriculture Organization of the United Nations; 2003 [accessed 2021 May 11]. http://www.fao.org/3/y5499e/y5499e00.htm#Contents.

- Gong YY, Routledge M, Kimanya ME, Musoke G, Nelson F, Sonoiya S, Manyong V. Building an aflatoxin safe East African community. In aflatoxin standards for food: knowledge platform 2015 – situational analysis East Africa region. 2015; Technical Policy Paper 8. https://aflasafe.com/wp-content/uploads/pdf/TPP-8-Aflatoxin-Standards-for-Food.pdf.

- Electronic Code of Federal Regulations. C.F.R. §966.50 Reconditioning failing quality peanuts. Washington (DC): US Government Publishing Office; 2021 [accessed 2021 Feb 17]. https://www.ecfr.gov/cgi-bin/text-idx?SID=d8ebf468075e5dbe07e3ced7db456552&mc=true&node=pt7.8.996&rgn=div5#se7.8.996_150.

- U.S. Department of Agriculture Grain Inspection, Packers and Stockyards Administration Federal Grain Inspection Service. Aflatoxin Handbook Chapter 1. Washington (DC): USDA; 2009 [accessed 2021 Feb 17]. http://www.angusbeefbulletin.com/extra/2012/10oct12/images/2012%20Aflatoxin%20Information.pdf.

- FDA Sec. 683.100 Action levels for aflatoxins in animal food compliance policy guide. Rockville (MD): 2019 [accessed 2021 Feb 17]. https://www.fda.gov/media/121202/download.