Clogging is a major issue in micro-irrigation systems, which can cause poor water distribution and requires regular maintenance for optimum irrigation system performance. This publication provides information about the causes of clogging in micro-irrigation systems and how to prevent and ameliorate clogging. This information will be helpful for growers utilizing micro-irrigation systems to irrigate/fertigate vegetable and fruit crops, nursery crops, row crops, and greenhouse crops.

Micro-irrigation is a low-pressure irrigation system that delivers water to plants via spray, mist, or drip (figure 1) and is applied in a wide range of situations, including orchards, vegetables, row crops, home gardens, nurseries, and greenhouses. The major advantages of utilizing micro-irrigation systems are a reduction in water usage, weeds, and disease prevalence.1,2 Micro-irrigation systems can be automated to facilitate precise irrigation scheduling and fertigation (application of fertilizers dissolved in irrigation water).1 One major disadvantage of micro-irrigation systems is increased maintenance costs, among which maintenance for clogging is one of the major issues. The emitters of micro-irrigation systems can become clogged with a variety of different particles, including soil and biological particles (bacteria, biofilms, algae, etc.) and/or chemical precipitates.3,9

Figure 1. The drip irrigation system (left) is a type of micro-irrigation system that irrigates by allowing water to drip slowly close to plant roots, either above the surface or buried below the surface (under the crop canopy). The rain gun sprinkler irrigation system (right) is a type of irrigation system that applies irrigation in the form of rainfall over the crop canopy.10 Image credit: Bhupinder Singh Jatana, Clemson University.

Clogging Problems with Micro-Irrigation Systems

Clogging of emitters can easily occur in micro-irrigation systems. When emitters are clogged, the pressure throughout the system can be altered, which can lead to inconsistent irrigation and nutrient applications. Clogs can be caused by suspended materials in irrigation water (from surface water), chemical precipitation (from groundwater and fertilizers), biological growth such as algae, bacterial slimes, or biofilms (figure 2, from surface water and well pipes), root intrusions, and soil ingestion.3,4,9 The best way to deal with a clog is to prevent it from happening, which can be done through proper filtration, chemical treatments, paying attention to types of fertilizers or other chemicals injected, as well as through periodically flushing the irrigation lines.5 Clogging by suspended materials (such as sand, silt, clay, plastics, algae, moss, bacterial slimes, or animal waste) in water can be prevented with a proper in-line filtration unit. Clogging with chemical precipitates commonly occurs when groundwater used for micro-irrigation contains high levels of minerals such as calcium carbonates, iron, and manganese etc.2,9 Clogging can also be caused by the chemical precipitation of fertilizers injected into the micro-irrigation system. The fertilizer that is injected can either react with other fertilizers or pesticides in the mixture (incompatible fertilizers or pesticides) or minerals in irrigation water and form precipitates.6 Biological growth can occur throughout the irrigation lines and emitters, and if not controlled, can become clog emitters. Biological growth is typically more common when the system utilizes surface water from a reservoir or pond for micro-irrigation. However, iron bacteria can still cause clogs when using well water.3 Root intrusions can occur when plant roots manage to grow and enter an emitter within the delivery piping of the micro-irrigation system. This often happens when roots are seeking water because they are irrigated at a lower rate than the plant demands.2 Soil clogging into the micro-irrigation lines and emitters occurs when water drains out of a drip line, creating a suction that can pull soil particles into the irrigation line/emitters and potentially clog them.3

Figure 2. A surface water reservoir used for irrigation contaminated with algae and other biological growth. Image credit: Bhupinder Singh Jatana, Clemson University.

Predicting Clogging Hazard

Water source: A water quality analysis often predicts an emitter-clogging hazard. Minerals in groundwater used for irrigation/fertigation can lead to the formation of chemical precipitates that can lead to clogging of the micro-irrigation system.7 This can be especially useful if a micro-irrigation system is new or even in the planning stages. If there is an indication that emitter clogging is likely, system design changes or maintenance procedures can be implemented to mitigate the problem.9

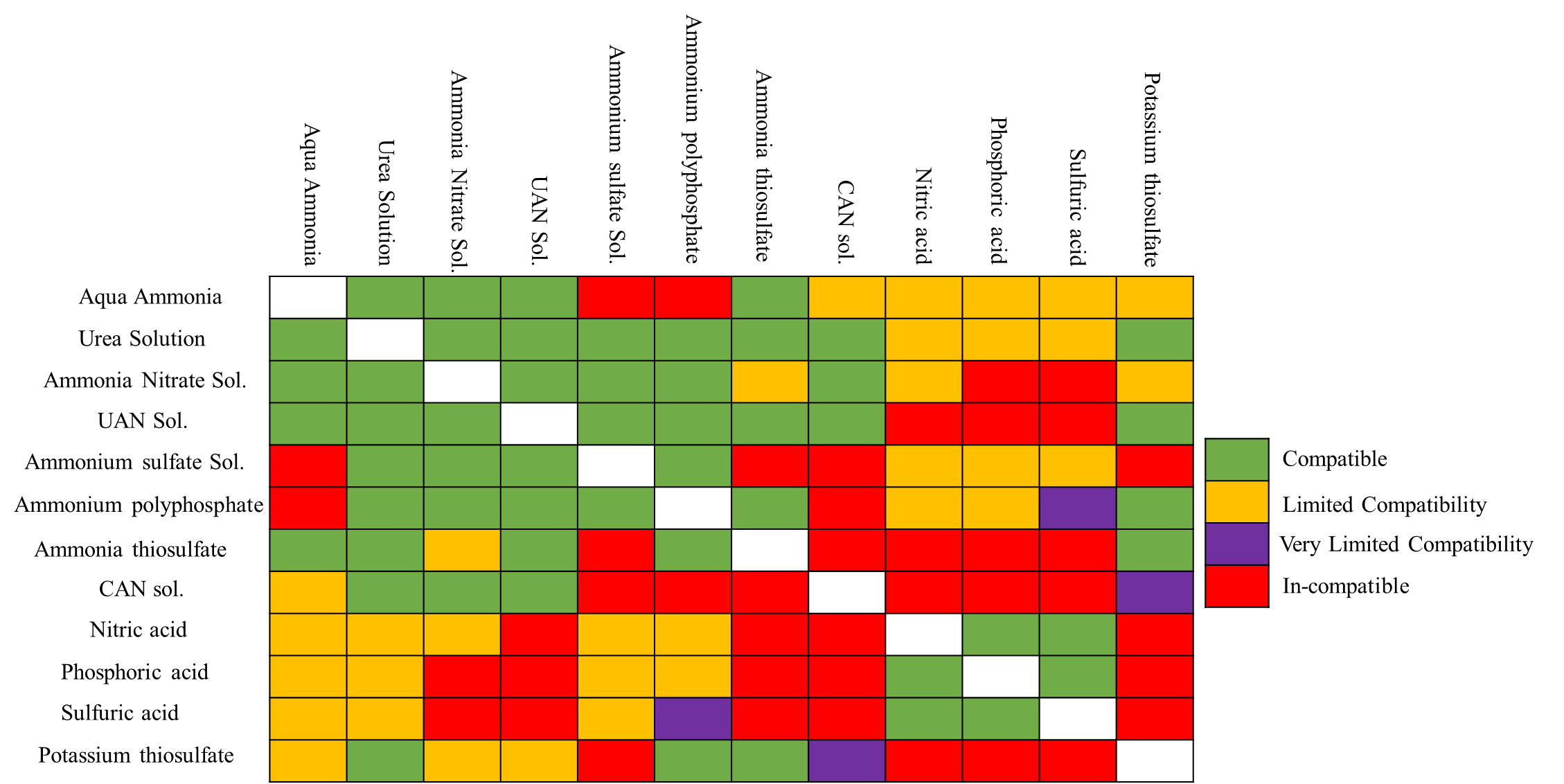

Fertilizer reactions – fertilizer incompatibility: Check the fertilizer compatibility chart before mixing the fertilizers for fertigation, as not all fertilizers are compatible with each other (figure 3). For example, calcium nitrate and diammonium phosphate fertilizers are commonly used for commercial crop production, but these two fertilizers are not compatible and can form calcium phosphate precipitates, which are insoluble and clog lines and emitters during fertigation.

Figure 3. Liquid fertilizer mixing compatibility chart. The color of the intersection of columns and rows states fertilizer compatibility, which means whether fertilizers can be mixed with each other or not. (i.e., Aqua ammonia is compatible with ammonium nitrate solution but incompatible with ammonium sulfate solution). Image credit: Bhupinder Singh Jatana, Clemson University.

Chemical reactions – fertilizers and water: There may be additional chemical reactions after selected fertilizers are injected into irrigation water. These reactions include hydrolysis, dissociation, oxidization, and precipitation.6 These chemical reactions can cause clogging. For example, Ferric ions in irrigation water can precipitate with different fertilizer anions, such as phosphate and sulfide.6 At high pH (more than 8), both calcium and magnesium in irrigation water can precipitate phosphate and clog the micro-irrigation system.6 There is also potential for fertilizers to react with pesticides when they are mixed. Read the entire pesticide label to determine if there are any known incompatibilities with fertilizers or other pesticides.

Maintenance of the Micro-Irrigation System

Flushing Micro-Irrigation Lines

The best way to clear most clogs in a micro-irrigation system is to flush the lines. Depending on the frequency and severity of the clog, the system may need to be flushed more or less frequently to help prevent and clear clogs.5 The method by which the lines are flushed depends on the type of clog that is present. The first step in determining how the lines should be flushed is to determine the nature of the clog. To effectively flush the pipes in a system, there needs to be a way to open the ends of the lines to allow water to pass through the pipes and out the other end. Another factor that can affect the effectiveness of flushing is the flushing velocity. A velocity of 1 fps (foot per second) is generally required, though higher velocities will be more effective.5 There are three main ways to flush the pipes in a micro-irrigation system.

Clean Water Flushing

Clean water typically clears out soil ingestions and other suspended materials. An important factor in this method is to ensure that the water is moving through the system at a high enough rate to effectively displace and move the clogs. It is generally a good idea to first flush the pipes into a cloth or a clean bucket to determine the type and/or quantity of materials that were suspended.5 The more materials that come out may indicate flushing needs to be done more frequently. The duration of the flushing differs on a case-to-case basis. Flushing should be done until the water runs clean. This can take anywhere from one to two minutes to much longer depending on a variety of factors, such as the severity and type of clog as well as the flushing velocity of the water.5 Generally, flushing the system with clean water is a good way to determine if other flushing methods are needed.

Chlorination

If flushing with clean water reveals the presence of biological growth in the pipelines, flushing with chlorinated water may be required. Chlorination is the process of flushing with lightly chlorinated water through the irrigation lines to eliminate most, if not all, biological clogs. A 50-ppm solution of chlorinated water can be injected through the system for about two hours to do chlorination. Afterward, let the chlorinated water remain in the pipes for about twenty-four hours to maximize the cleaning. After twenty-four hours, flush clean water through the irrigation lines.3

If ferric precipitates clog the irrigation line, inject chlorine at a concentration of 0.64 times the ferrous or soluble iron concentration (through irrigation water analysis) to maintain 1 ppm of free residual chlorine at the end of the drip line.9 Visit the Clemson University Agricultural Service Laboratory website for information about irrigation water analysis services. Chlorine oxidizes the iron at a lower pH. For practical purposes, however, a pH of about 6.5 to 7.5 is recommended for chlorine oxidation.8 Inject chlorine at a concentration of 1.3 times the soluble manganese concentration to clear manganese precipitates.8 While chlorination can be a great way to remove some types of clogs from your irrigation lines, if done incorrectly, it can have harmful effects on your plants. As seen in table 1, the effect chlorination has on plants depends primarily on the age and type of plants.

Table 1. Threshold of chlorine (ppm) that can be tolerated by selected crops before phytotoxicity.8

| Commodity | Chlorine threshold (ppm) |

| Vegetable seedlings | <1 |

| Peppers | >8 |

| Tomatoes | >8 |

| Sweet peppers | >50 |

| Broccoli | >37 |

Acidification

Figure 4. Mineral precipitate clogging (circled) in a drip line installed to irrigate/fertigate bell pepper. Image credit: Guodong Liu, UF/IFAS Extension, “How to Reduce Clogging Problems in Fertigation.”

If, instead of biological growths, mineral precipitates are being flaked off the pipe walls (figure 4), then acidification may be the best solution. Acidification of the lines will help to dissolve any chemical precipitation. Keeping the water slightly acidic throughout the lifetime of the pipelines can inhibit chemical precipitates from forming. Lowering the pH of irrigation water to below 7 can inhibit the formation of some chemical precipitates, such as calcium carbonate or lime.3 If chemical precipitates have already been formed and have clogged the lines, acidified water of pH 5 should be injected into the lines and kept there for twenty-four hours before flushing with clean water.3 Injecting acidified water with a pH lower than 5 can sometimes cause emitter problems depending on the material the emitters are made of. For example, in some pressure-compensating emitters, the flexible head can be damaged by a pH of 4 or lower. Brass valves can also be damaged by a pH of 4 or lower as well.3 Contact the manufacturer of the emitter to find out the lowest pH allowed. Additionally, acid and chlorine should never be stored or mixed, as this can cause the formation of chlorine gas, which is highly hazardous.3

Additional Maintenance Needs

Over time, micro-irrigation systems may need to be replaced. This can be due to damage such as leaks, often caused by animals or equipment, or clogs that cannot be flushed out. If flushing with either water, chlorine, or acid does not clear the clog, the emitters may need to be replaced. Some micro-irrigation systems have replaceable parts, which may make the job easier, while others may require replacing the entire system. Often, installing another emitter near the clog may be easier than replacing the system. However, this is not always an option since many pipelines and emitters are permanently sealed.3,10

Other parts of micro-irrigation systems may need to be cleaned or replaced over time. One of which is a filtration unit installed to filter large particles such as sand, silt, etc. Over time, filters can become clogged with biological growth and need chlorination by pouring half a gallon of chlorine bleach into the filtration unit and filling the rest with water.3 However, it is imperative that the field valve is closed during the chlorination of the filtration unit to ensure thorough cleaning. Let the bleach/water mixture soak for six hours before washing the filtration unit with clean water.9

Summary

Micro-irrigation systems are a useful tool for growers to increase water and nutrient use efficiency and yields. Despite many advantages, there are a few challenges of micro-irrigation systems, the most common of which is dripline/emitter clogging. Lines can often become clogged for a variety of reasons, including biological, soil, and/or chemical precipitates. Flushing with clean water through irrigation lines is a great way to assess the presence of any clogs in micro-irrigation lines. If flushing reveals the presence of clogs, action can be taken to alleviate the issue. For biological clogs, flushing chlorinated water through the lines can help eliminate biological growths and/or clogs. In case of soil particles, flushing clean water at a relatively high velocity can often wash out the clogs, and soil particles can usually be prevented altogether by installing a filter in line. For chemical precipitates, flushing with acidic water through the system can clear the clogs. However, the strength of the acid largely depends upon the type and severity of the chemical clog. Other maintenance needs of micro-irrigation systems include cleaning and/or replacing individual system parts (e.g., hose, emitters, filters, etc.). Micro-irrigation systems may increase the production of farms, nurseries, and/or home gardens, and understanding their proper management can allow their prolonged utilization and improve efficiency.

References Cited

- Hla A, Scherer T. Introduction to micro-irrigation. Fargo (ND): North Dakota State University. NDSU Extension Service; 2003 March. AE 1243. https://library.ndsu.edu/ir/bitstream/handle/10365/5108/ae1243.pdf?sequence=1.

- Evans R, Wu I.-P, Smajstrala A. Chapter 17. Micro-irrigation systems. St. Joseph (MI): ASABE (American Society of Agricultural and Biological Engineers) Technical Information Library. https://elibrary.asabe.org/abstract.asp?aid=23700.

- Schwankl L, Hanson B, Prichard T. Maintaining micro-irrigation systems. Oakland (CA): University of California, Agriculture and Natural Resources; 2008. 21641.

- Goyal M, editor. Management, performance, and applications of micro-irrigation systems. Oakville (ON): Apple Academic Press; 2014.

- Smajstrala A, Boman B. Flushing procedures for micro-irrigation Systems. Gainesville (FL): University of Florida IFAS (Institute of Food and Agricultural Sciences) Extension; 2002 Jul. Bulletin 333. https://irrigationtoolbox.com/ReferenceDocuments/Extension/Florida/WI01300.pdf.

- Liu G, McAvoy G. How to reduce clogging problems in fertigation. Gainesville (FL): University of Florida IFAS (Institute of Food and Agricultural Sciences) Extension; 2021 Sep. PUBLICATION #HS1202. https://edis.ifas.ufl.edu/publication/HS1202.

- Haman D. Causes and prevention of emitter plugging in microirrigation systems. Gainesville (FL): University of Florida IFAS (Institute of Food and Agricultural Sciences) Extension; 2022 Feb. https://edis.ifas.ufl.edu/publication/ae032.

- Dery J, Gerrity D, Rock C. Minimizing risks: use of surface water in pre-harvest agricultural irrigation; part ii: sodium and calcium hypochlorite (chlorine) treatment methods. Tucson (AZ): University of Arizona Cooperative Extension; 2020 Jul. az1831. https://extension.arizona.edu/sites/extension.arizona.edu/files/pubs/az1831-2020.pdf.

- Ahmed B, Tilaye A, Bedhaso C. Adaptation and evaluation of portable gun type sprinkler irrigation for smallholder farmers. American Journal of Agricultural Science, Engineering, and Technology. 2023 Sep;7(3):32–36. doi:10.54536/ajaset.v7i3.1936.

Additional Resources

Maintenance of Micro-Irrigation Systems. Oakland (CA): University of California and W-2128; 2024. https://micromaintain.ucanr.edu/.

EPA. Adding Micro-irrigation to your services: A mini-guide for irrigation professionals. Washington (DC): EPA (United States Environmental Protection Agency), EPA Water Sense; 2018 May. 4204M. EPA 832-F-18-004. https://www.epa.gov/sites/default/files/2018-05/documents/ws-outdoors-microirrigation-prosguide.pdf.