Using alternative agricultural methods to produce food for family consumption or generate income has gained interest due to recent food safety concerns with commercially cultivated produce, the smaller footprint required, and the ease of regulating production factors. One increasingly popular alternative method is aquaponic production, which allows for fresh vegetable produce and healthy fish protein. This publication covers the different components of an aquaponics system, their purpose, and the mechanisms that connect the system and allow for proper operation. The information presented below will offer insight into the various components of an aquaponics system and the functionality and significance of each component for the efficient operation of a system.

Introduction

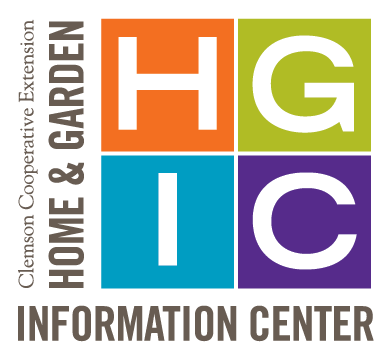

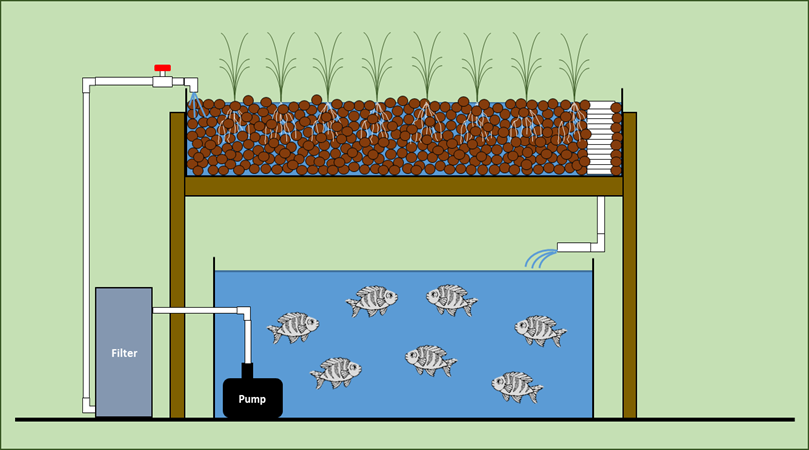

Figure 1. Diagram depicting the critical steps in the operation of an aquaponics system. Image credit: Lance Beecher, Clemson University.

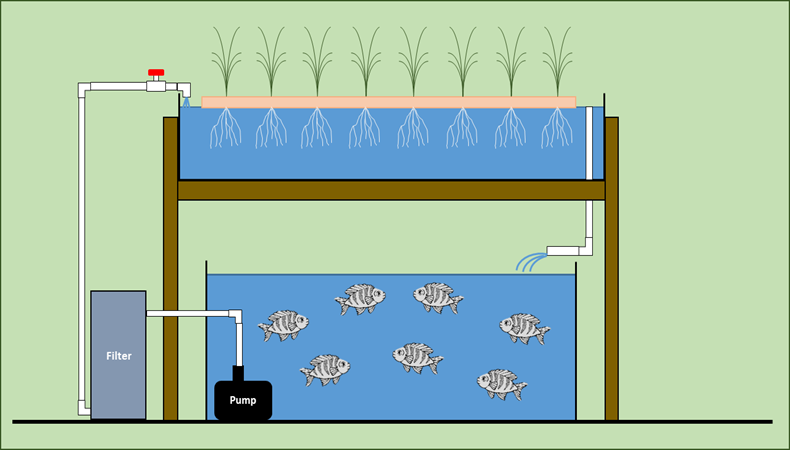

How does an aquaponics system operate? To begin, fish are cultured in tanks and fed a proper diet (fish food) that first introduces nitrogen to the system; in turn, the fish consume the feed, which begins processing, or breakdown, of food into protein for meat production (figure 1). When digestion and breakdown of the food occurs, waste is generated and excreted by the fish and enters the water recirculating through the system. Waste is carried to the filter, where solids are captured, and bacteria are present for nitrification to take place. Nitrification is the process by which ammonia (NH4) is converted to nitrite (NO2), then to nitrate (NO3), by specific beneficial bacterial cultured in the filter and throughout the aquaponics system. Nutrient-rich water leaves the filter and is delivered to the plants, serving as a fertilizer. As plants absorb nutrients from the recirculated water, clean water exits the plant growing area and returns to the fish tank. These processes, when combined, are all part of the integral design of an aquaponics system.1,2

Components Purpose and Design Principles

Fish Tank

Figure 2. IBC totes are commonly used to construct an aquaponics system. Image credit: Lance Beecher, Clemson University.

The fish tank is essential for fish culture and should be large enough to allow the fish to thrive and grow. Fish have to be comfortable and stress-free in the tank so that the system operates efficiently. Criteria for fish tanks can include if the container is new or used, the manufactured material, and the size and shape of the tank. It’s often cost-effective to use a recycled tank in an aquaponics system; however, the history of the tank container is essential knowledge. As an example, liquid totes are available from liquid shipping transporters (figure 2); however, if that tote initially stored harmful chemicals or any other substances that may be harmful to fish, it should be discarded or used for other purposes.

Dependable material used in fish tank manufacturing includes polypropylene, high-density polyethylene, and fiberglass for preformed tanks and PVC or EPDM lining material for self-constructed containers (figure 3). The budget typically determines fish tank material preference. However, with adequate pre-planning, one can select a decent tank. Tank sizing depends on a few factors:

- The total area dedicated to the system

- The primary purpose (fish or plant production), and

- Tank characteristic (pre-molded or assembly required)

Also, consider tank shape as the tank profile regulates water circulation within the tank, allowing for efficient waste removal and good water quality in the fish tank providing suitable habitat for fish production.3

Figure 3. Plastic, fiberglass, or wood and liner material (from left to right) are used to construct fish tanks for use in aquaponics systems. Image credit: Lance Beecher, Clemson University.

Water Filtration

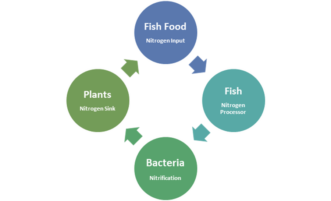

Water filtration sizing and design are crucial for a productive aquaponics system.4 Filtration is vital for both solids removal (mechanical) and bacterial conversion (biological) of waste products generated by the fish into essential nutrients required by the plants for development. Mechanical filtration is principally filtering and removing all visible solids in the water column. Solids within the water column include fish fecal matter, uneaten feed, suspended bacterial colonies, and other inorganic material. Solids are removed from the system immediately via settling, as solids place an extra burden on the filtration unit (figure 4). For example, if solids remain in the system, heterotrophic bacteria begin to colonize and degrade solids. As solids degradation begins, the bacteria consume dissolved oxygen from the system as they produce ammonia. Higher concentrations of ammonia combined with diminished dissolved oxygen in the water require the beneficial nitrifying bacteria community to expend more energy to transform ammonia into nitrate. Nitrate is the form of nitrogen more readily absorbed by plants.

There are two approaches to mechanical filtration in an aquaponics system. One is passive, where water flows through the filter by gravity. The other is active, where the water pump pushes water through the filter. One advantage of passive filtration is the solids come to the filter unit intact, so the larger solids are quickly captured (figure 4A). However, a disadvantage is careful planning and constant adjustment necessary to ensure proper flow is maintained with gravity to keep the water clean.

Once solids are removed, biological filtration using an aerated mixed media bed (figure 4B) is needed to convert harmful ammonia and nitrite to less toxic (to fish) nitrate, an essential nutrient for plant growth.5 Most biofilters are easy to design and are very efficient, with not much of an investment.

Figure 4. Solids settling device (A) is used to remove solids in an aquaponics system and (B) mixed media bed is used for biological filtration in an aquaponics system. Image credit: Lance Beecher, Clemson University.

Three main requirements are needed to establish a productive biofilter: water flow, surface area, and dissolved oxygen.6 Sufficient water flow carries dissolved waste to the biofilter. As water passes through a media bed, nitrifying bacteria convert ammonia and nitrite into nitrate. The conversion process is referred to as nitrification and is crucial for correct system operation. Various substrates can serve as the media in the biofilter, though most filters are filled with lightweight plastic materials that are available in different sizes and shapes (figure 5). The media in the filter provides surface area for nitrifying bacteria to adhere to in the filter unit. The converted waste then becomes necessary nutrients for the plants to absorb. The last requirement for proper biofiltration is an adequate level of dissolved oxygen dispersed throughout the whole biofilter to support nitrogen conversion by the bacteria. These bacteria consume oxygen, and if dissolved oxygen levels fall below a minimum threshold of 6 mg/L of dissolved oxygen, there can be disruptions in ammonia transformation and formation of zones within the media bed completely without oxygen (i.e., dead zones).

Figure 5. Lightweight plastic media is used in biological systems and provides surface area for nitrifying bacteria. Image credit: Lance Beecher and Sarah White, Clemson University.

Water Movement and Aeration

It is essential to provide proper water flow to carry waste to the filtration device and nutrient-rich water to the plant system. The solution is a properly sized water pump that offers this need for water circulation. A water pump can be either submersible or inline (figure 6). Both pumps provide efficient water flow, and the decision to use either is mainly up to the system owner. Submersible pumps are designed to be submerged within the fish tank and are often used in smaller systems where experience with plumbing is not needed. To extend the life of the pump, purchase and use a submersible pump rated for continuous use. An inline pump is external to the tank and plumbed inline within the system. It is slightly more challenging to plumb in an inline pump; however, inline pumps are relatively efficient in moving water through the system. Inline pumps are typically more powerful and are mainly used on larger systems where system plumbing is much more complicated.

Figure 6. Various pumps are used in aquaponic systems. Pumps used include a small (left) and large (middle) submersible water pumps and an inline water pump (right). Image credit: Lance Beecher, Clemson University.

Figure 7. Aeration equipment used in an aquaponic system. Image credit: Lance Beecher, Clemson University.

Aeration in aquaponics systems is critical for providing adequate dissolved oxygen for fish survival, beneficial bacteria in the filter unit, and proper levels for plant growth. An air pump, which produces compressed air, tubing to carry the compressed air to the bottom of the tank, and air stones to bubble air into the system, make up the aeration system (figure 7). Comparable to water flow, it is essential to size the aeration system accurately to provide a sufficient level of dissolved oxygen throughout the aquaponic system. Aeration also provides water movement in the unit to help deliver suspended solids to the filtration system.

Plant Systems

The portion of an aquaponics unit that is the most productive is the plant system containing selected vegetables for harvesting.7 Seeds germination takes place in Rockwool, and plants are allowed to establish a viable root system in a small grow unit, then small plants are transferred to the final grow-out system. A variety of plant systems can be successfully managed in an aquaponics unit. The plant system selected depends on the type of production that suits the plant being grown.

Deep Well System

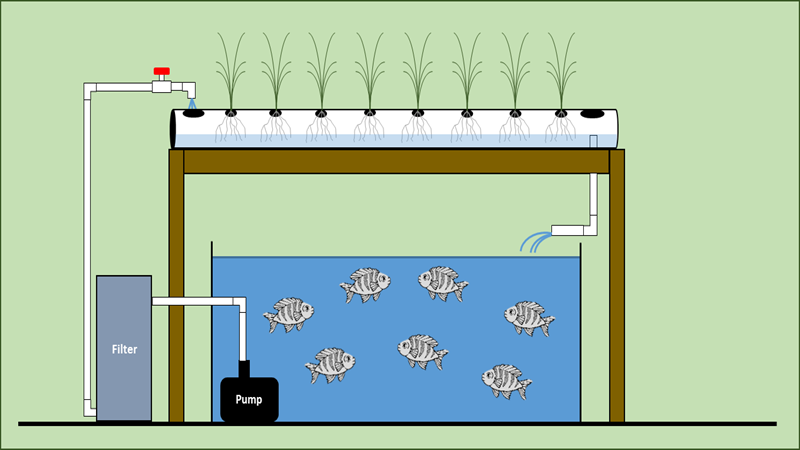

The deep water or “raft” system is probably the most popular for fast-growing plants with a short life, harvested as a whole plant (figure 8). The construction is simple and consists of a trough holding water about six to eight inches in depth and usually four to eight feet wide and can be as long as one hundred feet. The width is often not more than eight feet because the plants should be inspected daily for pests and disease. Nutrient-rich, well-oxygenated water is dispersed in one end of the system, moves through the trough, and exits the opposite end. If the channel is longer than twenty-five feet, water inlets can be spaced at specific intervals to ensure nutrient levels are sufficient throughout the entire bed. Supplemental aeration can also be applied to sustain adequate dissolved oxygen levels for a successful crop.

Figure 8. Diagram of the “deep well” or “raft” system, allowing the plant roots to suspend freely in the water. Image credit: Lance Beecher, Clemson University.

Ebb and Flow Systems

The ebb and flow or flood/drain media bed system is probably the most diverse plant system that is practical for an aquaponics unit (figure 9). For example, this system allows fast-growing lettuce to grow adjacent to long-growing, fruit-bearing tomatoes. The ebb and flood growing system is also widely accepted because plants are grown in a medium that mimics the soil, providing additional structural support. The medium usually consists of a substrate (e.g., clay) formed into a specific shape or any inert porous material that drains easily. The system operates by slowly allowing nutrient-rich water to enter the tray and fill up to a particular level. A “bell siphon” is used to automatically siphon water out of the system until the bin is almost empty. Once the water reaches the bottom of the siphon, air breaks the process, and the tray begins to fill again. This flood/drain process can be controlled and allowed to sequence a set number of times per day. One difference with this system is that sufficient dissolved oxygen levels in the incoming water are not as critical because the plant root zones are reaerated when the tray drains.

Figure 9. The ebb and flow plant growing system allows a variety of plants to thrive in the system. Image credit: Lance Beecher, Clemson University.

Nutrient Film Technology System

The aquaponics-adapted Nutrient Film Technology (NFT) system offers versatility for fast- and long-growth cycle plants. The actual NFT system is used extensively in the hydroponics industry and is highly productive. Adjustments are made to the traditional NFT system to function in an aquaponics unit. These adjustments include replacing smaller diameter tubing with larger diameter pipe material because of excessive bacterial growth clogging the smaller diameter tubing. Also, large-diameter PVC pipe (4- and 6-inch) could be used as channels instead of expensive commercially available channel material for plant cultivation (figure 10).

Figure 10. The hybrid Nutrient Film Technology system can be integrated within an aquaponics system. Image credit: Lance Beecher, Clemson University.

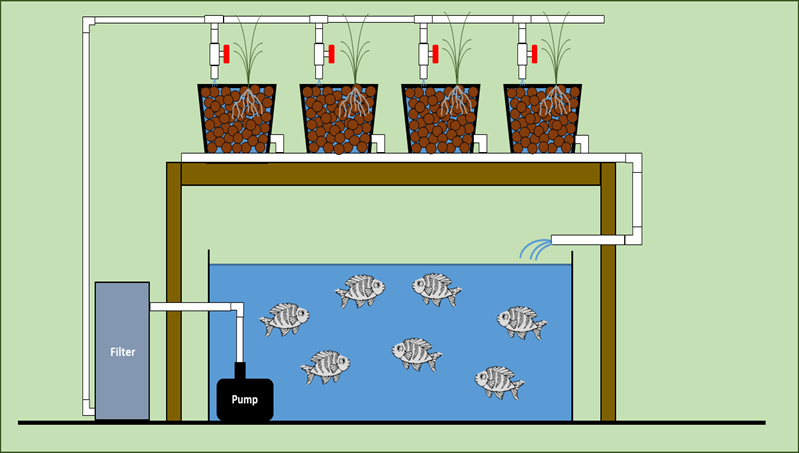

Bucket System

The dutch bucket system (figure 11) is another hydroponic production system used to successfully cultivate vining vegetables in aquaponics, though it can be used to grow any vegetable. Nutrient water is allowed to enter the bucket and trickle through a medium encompassing the plant roots or by flooding from beneath. The plants absorb the nutrients as water passes by the root structure. Water exits the bucket through a drain located at the bottom of the bucket. Water does not accumulate and fill the bucket, so the plant root systems remain aerated, even under continuous flow conditions.

Figure 11. The bucket system is a very efficient system for growing vining vegetables in the aquaponics system. Image credit: Lance Beecher, Clemson University.

Summary

Insight and careful consideration are necessary to construct a functional and efficient aquaponics system. The information presented in this article allows owners to consider all options and adjust or modify their own specific production requirements. There are specific equipment requirements needed to provide a healthy environment for both the fish and plants. This publication describes what is necessary and offers information to understand why it is essential to have these components for a productive aquaponics system.

References Cited

- Rakocy JE, Masser MP, Losordo M. Recirculating aquaculture tank production systems: aquaponics – integrating fish and plant culture. Stoneville (MS): Southern Regional Aquaculture Center (SRAC); 2006. SRAC Publication No. 454.

- Rakocy J. Ten guidelines for aquaponics systems. Aquaponics Journal. 2007;46:14–17.

- Timmons MB, Ebeling JM, Wheaton FW, Summerfelt ST, Vinci BJ. Recirculating aquaculture systems. 2nd ed. Ithaca (NY): Cayuga Aqua Ventures, LLC; 2002.

- Malone RF, Beecher LE. Use of floating bead filters to recondition recirculating waters in warmwater high-density aquaculture production systems. Aquaculture Engineering. 2000;22(1):57–73.

- Kuhn DD, Drahos DD, Marsh L, Flick GL. Evaluation of nitrifying bacteria product to improve nitrification efficacy in recirculating aquaculture systems. Aquaculture Engineering 2010;43:78–82.

- Delong DP, Lasordo TM. How to start a biofilter. Stoneville (MS): Southern Regional Aquaculture Center (SRAC); 2012. SRAC Publication No. 4502.

- Lennard WA, Leonard BV. A comparison of three different hydroponic sub-systems (gravel bed, floating, and nutrient film technique) in an aquaponic test system. Aquaculture International. 2006;14:539–550.

Additional Resources

Beecher L. Introduction to Aquaponics. Clemson (SC): Clemson Cooperative Extension, Land-Grant Press by Clemson Extension; 2021 Jun. LGP 1113. https://lgpress.clemson.edu/publication/introduction-to-aquaponics.