While professional users of chainsaws must follow Occupational Safety and Health Administration (OSHA) requirements to keep them safe, the non-professional user is not subject to the same requirements. Therefore, many non-professional users are unfamiliar with the safety features of chainsaws and the personal protective equipment (PPE). Chainsaws are powerful tools to cut trees and are often used by professional loggers and arborists. The first mobile and gas-powered chainsaws were produced in the late 1920s and early 1930s and were purpose-built for forestry work and logging.1,2 However, with today’s mechanization in the logging industry, chainsaws have vastly disappeared from professional logging sites.3,4 Instead, chainsaws have found new and continued use with private forest owners, farmers, and homeowners. The purpose of this publication is to inform non-professional users about the health risks that chainsaws can pose, the safety features present on all modern chainsaws, the personal protective equipment available to keep them safe, and safe operating practices.

Health Risks

According to 1994 data from the US Product Safety Commission, chainsaw-related injuries occur from head to toe.5 The majority of injuries occur on the arm and hand area (42%) and the leg area (38%), with more injuries occurring on the left side of the body. Injuries to the head (8%), foot (7%), and upper body (5%) areas are less likely but still occur. An evaluation of chainsaw injuries in the United States between 2009 and 2013 that resulted in a visit to the emergency room showed that 81% of all reported injuries were lacerations, with the majority of injuries occurring on hands/fingers (29%), the knee (18%), and the lower leg/ankle (12.5%).6 In the same timeframe, an average of 23,179 reported chainsaw-related injuries occurred across the United States annually. Ninety-five percent of the injuries were incurred by males between 30 to 59 years of age.

A significant cause of injuries is chainsaw kickback and the loss of control of the saw.7 Kickback is the immediate push and backward motion of a chainsaw when the guide bar’s tip touches an object and typically is directed towards the upper body and head area. The video Kickback Demonstration (provided by Carl Groombridge on YouTube) demonstrates what kickback looks like. What makes these injuries even worse is that chainsaws are designed to “rip” material rather than “cut” it. Unlike a clean and smooth cut from a sharp knife, a chainsaw injury will leave ragged edges along the wound and remove about a quarter of an inch or more of muscle material from the body. Other injuries related to chainsaw use are injuries to the eye due to flying objects and hearing loss due to exposure to loud noises over a prolonged period.8

Many injuries can be prevented by proper training and the safe use of chainsaws, the safety features incorporated into modern chainsaws, and PPE. The professional logger must follow OSHA Standard 1910.266, which outlines required practices to handle a chainsaw, chainsaw safety features, and PPE.9 Most of these requirements are also good practices for the non-professional user of chainsaws, and we will expand on them in the following sections.

Chainsaw Safety Features

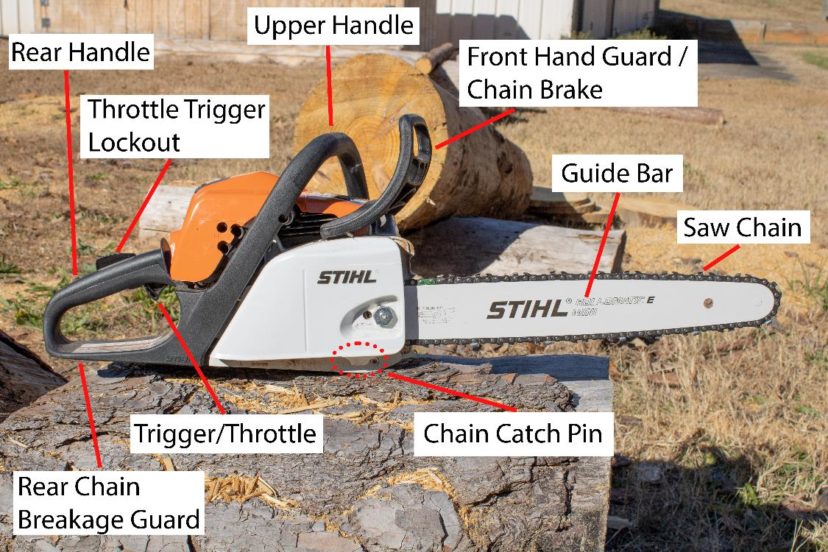

When looking at the OSHA Standard 1910.266, all chainsaws used in a professional logging operation must have a chain brake, a continuous pressure throttle control system, and comply with the ANSI (American National Standard Institute) safety standard B175.1-1991, Safety Requirements for Gasoline-Powered Chain Saws.9 For the non-professional user of chainsaws, it is essential to know that all modern chainsaws are equipped with four safety features that can significantly reduce the risk of injury: (1) chain brake, (2) inertia brake, (3) throttle trigger lockout, and (4) chain catch pin (figure 1). Consideration should be given to not using a chainsaw that is missing one or more of these safety features, as it poses a greater risk of injury than chainsaws equipped with these features.

Figure 1. Important parts of a chainsaw. Not shown in the picture is the inertia brake, which is an internal safety feature connected to the chain brake. Image credit: Patrick Hiesl, Clemson University.

Chain Brake

The chain brake (figure 1), introduced in 1972,2 is probably the most crucial safety feature of a chainsaw. Located in front of the upper handle in the form of the front hand guard, it is a mechanical feature that stops the saw chain from spinning around the guide bar when engaged. It does so by blocking the internal clutch and preventing it from engaging to rotate the saw chain. The chain brake is activated by pushing the front hand guard forward toward the guide bar. The front hand guard is pulled back towards the upper handle or the engine block to disengage the chain brake. Engaging and disengaging the chain brake should be done with both hands still on the chainsaw. Never take one hand off the chainsaw to engage or disengage the chain brake, as there is a risk of injury should one hand slide into the saw chain.

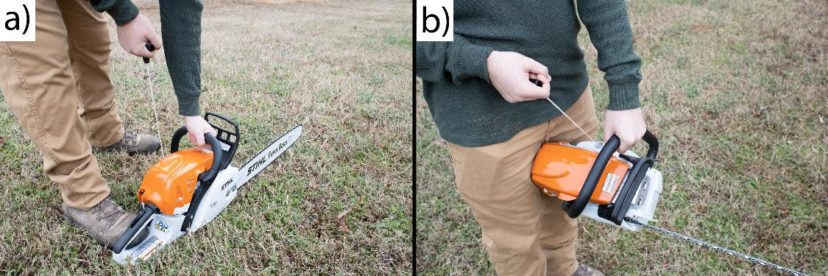

To engage the chain brake, the right hand should have a firm grip on the rear handle, the left hand should have a good but loose grip on the upper handle, and the left-hand wrist should be flicked forward to push against the front hand guard (figure 2a). To disengage the chain brake, the right hand should have a firm grip on the rear handle, and the thumb of the left hand should be “hooked” around the upper handle with the other four fingers grabbing the front hand guard and pulling it backward (figure 2b). When the chain brake is engaging (or disengaging), there will be a loud “click” sound. If this sound is not heard, either the chain brake has not been fully engaged or disengaged, or the chain brake is broken and needs to be replaced.

Figure 2. Correct and safe way to engage (a) and disengage (b) the chain brake. Image credit: Patrick Hiesl, Clemson University.

Inertia Brake

The inertia brake is part of the modern chain brake and is designed to engage the chain brake when an excessive force is applied to the chainsaw. The inertia brake is a protective function that will prevent or reduce injuries from chainsaw kickback situations. With kickback, the chainsaw will experience a fast acceleration towards the operator that, in many cases, is faster than the operator’s reaction time. An excessive force is displayed during this kickback motion that will automatically engage the chain brake. This feature was developed in 1982 and is present in all modern chainsaws.2 One way to test whether a chainsaw has a functioning inertia brake is to disengage the chain brake and then drop the tip of the guide bar onto a piece of wood from about shoulder height. When the tip of the guide bar hits the wood, there should be a “click” sound that signals that the chain brake is engaged. Watch the Testing the Chainsaw Safety Features video (provided by AutoTune TM on YouTube) for a demonstration of the inertia brake test. If, after three tries, this sound is not heard, the chain brake may be broken, and the chainsaw should not be used until a chainsaw dealer inspects it and confirms functionality.

Throttle Trigger Lockout

The throttle trigger lockout (figure 1) is a mechanical safety feature that prevents accidental acceleration of the saw chain without having a firm grip on the rear handle. It is a lever embedded in the top of the rear handle and locks out the trigger so that it cannot be depressed. The throttle trigger lockout is engaged when the lever sticks out of the rear handle top. To disengage it, the user must depress the throttle trigger lockout, which typically happens with the palm of the right hand as the user gets a grip on the rear handle. Once the trigger lockout is depressed, the trigger can be activated, and the saw chain accelerated. This safety feature forces the chainsaw operator to have a good grip on the rear handle of the chainsaw, prevents the accidental cutting of the right hand, and allows for better control of the chainsaw when in operation.

Chain Catch Pin

Another safety feature on chainsaws is the chain catch pin mounted on the underside of a chainsaw close to the guide bar (figure 3a). The purpose of the chain catch pin, as the name indicates, is to catch the chain if it “jumps” out of the guide bar grooves or breaks due to stress or material failure. Should one of these events happen, the saw chain will drop from the guide bar and naturally spin towards the operator. However, before the chain can reach the chainsaw operator, the chain catch pin will catch the chain and absorb a good portion of the power left in the chain. After the chain catches on the chain catch pin, the chain may continue to move towards the operator, but at a slower speed, and at worst, it will hit the underside of the rear handle and then lose all its power.

By design, the bottom of the rear handle is wider than the handle itself, with an extension towards the side of the saw chain. This part of the rear handle is called the rear chain breakage guard and will protect the right hand from any severe injuries. The chain catch pin comes in many different forms and shapes, from a round pin to a square pin to pins bent upwards like a hook (figures 3a and 3b). Some are made from plastic and may be part of the clutch cover (figure 3c), others are made from aluminum, and some have a protective coating. Chain catch pins can break off and should be replaced immediately to provide this safety feature to the user. Depending on the design of the chain catch pin, the replacement cost can range from a few dollars to close to $20.

Figure 3. Chain catch pins vary in form, size, and material. Image credit: Patrick Hiesl, Clemson University.

Personal Protective Equipment (PPE)

Personal protective equipment is the protective clothing an operator can wear to minimize bodily injuries in the case of an accident with a chainsaw. Professional loggers that work with a chainsaw have to follow a series of PPE requirements, including cut-resistant leg protection; water repellent/proof boots with ankle support and cut-resistant inlays; and face, eye, hearing, and hand protection.9,10 It is good practice for non-professional chainsaw users to wear the same PPE required for loggers.

Cut-Resistant Leg Protection

Figure 4. Cut-resistant clothing contains multiple layers of interwoven strings of cut-resistant materials. Image credit: Patrick Hiesl, Clemson University.

Cut-resistant leg protection means that the clothing worn on the legs includes some material that prevents the chainsaw from cutting deeply into a leg. Standard cut-resistant products are made from a polyester fabric shell with a core of multiple layers of ballistic nylon, Kevlar®, or other cut-resistant materials (figure 4). When cut by a saw chain tooth, the long strings within the core material will be caught and transported back inside the clutch cover. Inside the clutch cover, an accumulation of the cut-resistant material will jam the sprocket and clutch, stopping the saw chain. A video from the University of Applied Forest Sciences in Rottenburg, Germany, documenting a test of cut-resistant materials shows that the saw chain stops in less than one-fifth of a second.11

Cut-resistant leg protection is available in two forms, cut-resistant pants or cut-resistant chaps that can be worn over typical clothing. Professional forest workers commonly use cut-resistant pants; however, loggers who use chainsaws occasionally use cut-resistant chaps. Cut-resistant pants can cost between $120 and $300 or more, depending on the quality and additional features. On the other hand, cut-resistant chaps can be purchased for between $50 and $100 for apron-style chaps (figure 5) and $75 to $150 for wrap-around chaps (figure 6). Both chaps and pants come with a different number of cut-resistant layers. For the non-professional user, chaps or pants with six cut-resistant layers will be sufficient. Some professional chaps and pants may include nine layers of cut-resistant material.

Cut-resistant leg protection, often called chainsaw safety pants/chaps or chainsaw pants/chaps, are designed to stop the spinning of the saw chain on a gas-powered chainsaw. With the advancements in corded and battery-powered chainsaws, concern has grown about whether the chaps/pants will work with these chainsaws. Many manufacturers of chaps/pants include a disclaimer that the cut-resistant material may not stop the saw chain with electric (corded) or battery-powered chainsaws due to the higher torque provided by those saws.12 It is important to note that gas-powered chainsaws utilize a clutch and sprocket that engage when the engine speed increases. This clutch/sprocket system gets jammed with cut-resistant material, which then disengages the clutch and stops the saw chain.

Electric (corded) and battery-powered chainsaws do not utilize a clutch but are powered by an electric motor that reacts to the push of the trigger. An accumulation of cut-resistant material around the sprocket will not stop the saw chain. However, in many cases, the cut-resistant material will snag on the saw chain, slowing the chain or providing the chainsaw operator with a strong pull-motion that alerts the operator to remove the finger from the trigger. Electric and battery-powered chainsaws will stop almost immediately when the finger is removed from the trigger. While chaps/pants may not work the same with electric and battery-powered chainsaws, anecdotal reports on the Internet highlight the value of chaps/pants in preventing some more severe injuries.

Hearing and Eye Protection

Hearing and eye protection are two important safety precautions when using chainsaws. Many manufacturers produce a helmet system that provides head, hearing, and face protection. These helmet systems feature a helmet that protects the operator from falling objects, earmuffs mounted to the helmet, and a mesh face shield (figure 7). The earmuffs and face are adjustable and can be turned or lifted when the chainsaw is not in use.

Other hearing protection includes earmuffs without a helmet system, easily obtained from a hardware store. Earplugs are another option to protect operator hearing when using chainsaws. They come in soft foam versions designed for single-use and nylon versions intended to be washed and used multiple times (figure 8). The latter ones also often come with a cord connecting both earplugs, which allows them to be carried around the neck when not in use.

Impact-rated safety glasses that meet the ANSI Z87 standard provide eye protection and will not shatter into small pieces when an object hits, preventing additional injury from glass contacting the eyes. Compliant safety glasses will have “Z87+” printed somewhere on the frame of the safety glasses (figure 9). The Z87 designation identifies the standard they comply with, and the + symbol indicates the safety glasses have been impact-rated. Glasses without the Z87+ marking should be replaced with ones that meet the ANSI standard. A manufacturer’s mark may also be found in front of the Z87+ text (e.g., PZ87+).

Safety glasses come in many different shapes and forms, and it is essential to choose ones that fit well on the head and snug around the eyes, protecting the side and the front. Safety glasses also come with an anti-fog system, consisting of ventilation holes around the nose pads and underside of the lenses. These safety glasses often cost more than standard ones without an anti-fog system, but it is well worth the investment to avoid fogged glasses when working with a chainsaw. Safety glasses also come with clear and tinted lenses (figure 10). The tinted lenses act as sunglasses and have a UV filter built in. Tints come in many different styles, from light to dark, blue to black coloration, with or without a mirror effect, etc. It is essential to choose safety glasses that do not impair your view. Tinted safety glasses are excellent choices on sunny days but may not work as well on cloudy days or when working in a dark forest. Professional insurance carriers recommend safety glasses in addition to a helmet system’s face shield.

Hand Protection

Figure 11. Gloves are an essential safety feature and can be made of leather (left), fabric (right), or a combination of both (middle). Image credit: Patrick Hiesl, Clemson University.

Properly maintained saw chains are very sharp and can easily slice into one’s fingers. Gloves are essential to protect fingers whenever handling a saw chain and when working with a chainsaw to cut wood to protect from flying debris and cuts and scratches from vegetation surrounding the cutting site. Leather gloves are a good choice when dealing with saw chains. At a minimum, sturdy fabric gloves should be worn to protect against injury (figure 11). Some gloves are loose around the wrist, while others have a Velcro® strip to get a close fit around the wrist. Gloves that close at the wrist will block sawdust from accumulating in the gloves when cutting wood.

Foot Protection

Protecting an operator’s feet is as important as protecting other body parts. Professional loggers must wear boots with cut-resistant inlays. Cut-resistant boots come in different styles, such as cut-resistant rubber boots for wet weather (figure 12) or boots with laces like logging or hiking boots. Such boots can cost anywhere from $100 to $400 or more. While wearing boots with cut-resistant inlays is a good idea for the non-professional user, it may be unreasonable to buy a pair of boots for the occasional use of a chainsaw. Instead, it is recommended to wear boots with ankle support for firm footing when working with a chainsaw. When bucking logs, it may also be a good idea to wear boots with a steel or composite toe to further protect the feet. When not wearing boots with cut-resistant inlays, cut-resistant pants or chaps that reach the top of the foot should be worn to provide some level of cut protection.

Reactive Forces of a Chainsaw

Figure 13. Reactive forces and areas of importance along the guide bar. Image credit: Patrick Hiesl, Clemson University.

Different reactive forces are at play when operating a chainsaw on different parts of the saw chain. Each chainsaw in active operation has a push and pull action on the upper and lower portion of the guide bar (figure 13). The push action is caused by the saw chain rotating away from the power head and, as such, pushing the chainsaw away from the object the saw chain touches. The pull action is caused by the saw chain rotating towards the power head and, as such, pulling the chainsaw towards the object that the saw chain touches. The tip of the guide bar is rounded and consists of two important areas (figure 13).

Figure 14. During kickback, the chainsaw travels at a fast speed towards the operator’s face and shoulder area. Image credit: Patrick Hiesl, Clemson University.

The lower portion of the guide bar tip is the attack corner. It is safe to cut with this corner since the saw chain rotates towards the power head and creates a pull action. The upper part of the guide bar tip is the kickback corner and is of some danger to the chainsaw operator. In the kickback corner, the saw chain rotates away from the power head and simultaneously changes from a horizontal to a vertical downward motion. When an object touches the saw chain on the kickback corner, the push motion is not straight back but also upwards, creating the potential for a chainsaw to head towards the operator’s face and shoulder (figure 14). Due to the speed of the saw chain, when an object touches the kickback corner, the acceleration of the chainsaw towards the operator is faster than what most people can react to. Extra care must be applied when operating a chainsaw to avoid objects touching the kickback corner. The risk of kickback can further be increased by dull saw chains, improper filing of saw chains, improper body position (e.g., unstable footing, reaching with a chainsaw), and saw chain speed and tension.

Safe Operating Practices

The professional logger must follow OSHA standard 1910.266, which outlines a series of required operating practices. These practices are also beneficial to the non-professional user of chainsaws and will further help to prevent serious injuries. First, do not fuel a chainsaw within ten feet of an open flame or ignition source, and do not start a chainsaw within ten feet of a fuel source. Following this safety precaution should prevent accidental ignition of fuel. Next, ensure that the saw chain is tight and snug against the guide bar, then start the chainsaw on the ground (figure 15a) or with the rear handle firmly held between the thighs (figure 15b).

With either starting method, the operator will have three points of contact with the chainsaw: the left hand on the upper handle, the right hand on the starter cable, and either the rear handle between the thighs or one foot pushing down on the rear handle. Do not start a chainsaw using a drop start. The drop start method consists of pulling on the starter cable with one hand and dropping (pushing away) the chainsaw with the other hand on the upper handle. This starting method is unsafe as the chainsaw operator has limited control over the movement of the chainsaw once started. Also, the chain brake should always be engaged before starting the chainsaw. When a chainsaw is started using the choke settings, it will crank with a high idle speed, allowing the saw chain to start spinning. By engaging the chain brake before starting the chainsaw, the saw chain will not spin, preventing accidental cuts and injuries.

Figure 15. Two safe methods for starting a chainsaw: On the ground (a) and tightly held between the thighs (b). Image credit: Patrick Hiesl, Clemson University.

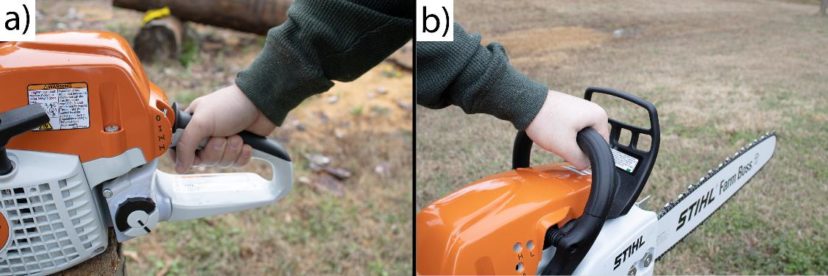

Safe operating practices also include having all fingers and the thumb gripping the rear handle (figure 16a) and the upper handle (figure 16b). This hold provides better control and minimizes the risk of losing contact with the chainsaw during a kickback event. Before cutting wood, whether for tree felling or bucking firewood logs, make sure to have secure footing. Stable footing will prevent any accidental slips and slides and minimize the risk of injury. Also, remove any brush or obstacles from the work area to reduce slip and fall hazards.

Figure 16. Proper holding of a chainsaw includes wrapping the thumb around the rear handle (a) and upper handle (b). Image credit: Patrick Hiesl, Clemson University.

The one practice that will likely prevent most accidental cuts is to engage the chain brake when moving. The OSHA standard for loggers is to engage the chain brake when moving more than fifty feet between cuts or less than fifty feet if the ground conditions may create hazards (e.g., terrain, underbrush, slippery surfaces). However, insurance companies often require that the chain brake be engaged when more than two steps are taken. For the non-professional user of chainsaws, it is recommended to engage the chain brake before moving to the next cut, regardless of the distance, and always have the chain brake engaged when the hands are not on the chainsaw. With a little bit of practice, engaging the chain brake after a cut is finished will become second nature and will significantly increase safety when working with chainsaws.

Do not cut above shoulder height. Once a chainsaw is raised above that height, the operator will lose some chainsaw control. Further, cut-resistant clothing is worn below the waist, and when operating above shoulder height, the upper body is fully exposed to accidental cuts without protection. When cutting above shoulder height, a pole saw should be utilized. Today, pole saws are also available with small motorized (gas or battery) chainsaw attachments, so operators no longer need to rely on a handsaw to cut those high-up branches.

Using properly sharpened saw chains is also essential when using a chainsaw. Saw chains that are dull or filed inconsistently can lead to operator fatigue due to increased operator-handling efforts or create hazardous conditions due to saw chain skipping and increased risk for kickback. Properly sharpening a saw chain is a skill that requires some practice and a deeper knowledge of the function of a saw chain and is not within the scope of this publication. Operators that are unsure about sharpening saw chains should have their saw chains professionally sharpened. Many chainsaw dealers offer this service for a fee. When sharpening a saw chain, it is important to wear gloves as many injuries to the hand occur during saw chain maintenance, and use a file with a handle covering the tang (the narrow and pointy part of a file) to reduce the risk of serious injury.

Many professional loggers carry a blood stopper or blood-clotting agent in their cut-resistant pants or chaps. Blood clotting agents come in many forms like powders and granules but can also be purchased integrated into a gauze pad. In addition to a simple first-aid kit for minor injuries, the blood-clotting agent can be a lifesaver when a severe cut occurs. Blood clotting agents can be purchased in pharmacies and online and cost anywhere from $10 to $40 or more. Just as with cut-resistant leg protection, this investment is well worth it.

Conclusion

In conclusion, chainsaws pose a particular risk for personal injury, but modern safety features, PPE, and safe operating practices can significantly reduce this risk. Using PPE and following safe operating practices will minimize the risk of injury, keep the non-professional user of chainsaws safer, and allow for more confidence when using a chainsaw. While this article provides an overview of how to stay safe when operating chainsaws, we recommend getting professional training for working with chainsaws, especially in a forested setting. The potential dangers of using chainsaws for felling trees and cleaning up storm-damaged trees are more significant than just the threat of being cut.

Contact your local Clemson Cooperative Extension county office for information on chainsaw safety training programs. Visit the Clemson Cooperative Extension website for county office contact information. Programs may also be offered by private chainsaw safety training program providers. The Game of Logging website has information about its training organizations although their programs are more commonly offered in the northern part of the country.

Acknowledgments

We would like to thank the South Carolina Sustainable Forestry Initiative (SFI) Implementation Committee for funding a series of chainsaw safety training workshops that allowed us to purchase the items shown in the pictures and led us to write this publication. We would also like to acknowledge the STIHL company for providing an educational discount for the various items pictured.

References Cited

- Haim G. Von der Fällmaschine zur modernen Motosäge. Wald und Holz. 2002;83(9):51–54.

- Thöny P. The history of the chainsaw. Birmesdorf (Switzerland): WaldWissen.net; 2007 [accessed 2021 Feb 12]. https://www.waldwissen.net/en/learning-and-teaching/forest-history/the-history-of-the-chainsaw.

- Conrad JL, Greene WD, Hiesl P. The evolution of logging businesses in Georgia 1987-2017 and South Carolina 2012-2017. Forest Science. 2018;64(6):671–681. https://academic.oup.com/forestscience/article/64/6/671/5043191. doi:10.1093/forsci/fxy020.

- Conrad JL, Greene WD, Hiesl P. A review of changes in U.S. logging businesses 1980s-Present. Journal of Forestry. 2018;116(3):291–303. doi:10.1093/jofore/fvx014.

- United States of Department of Labor. Logging eTool: csilWashington (DC): Occupational Safety and Health Administration (OSHA); [accessed 2021 Feb 12]. https://www.osha.gov/etools/logging/manual-operations/logger/chain-saw/saw-injuries.

- Hammig B, Jones C. Epidemiology of chain saw related injuries, United States: 2009 through 2013. Advances in Emergency Medicine. 2015;2015(459697):1–4. doi:10.1155/2015/459697

- State Compensation Insurance Fund. Cutting down on chainsaw injuries. Los Angeles (CA): State Fund; [accessed 2021 Feb 12] 2014. https://content.statefundca.com/safety/safetymeeting/SafetyMeetingArticle.aspx?ArticleID=788#:~:text=The most frequent chainsaw injuries occur to the kickback and losing control of the saw.

- Alliance of Forest Workers and Harvesters, Labor Occupational Health Program. U.C. Berkeley, editors. Chainsaw safety. Medford (OR): Alliance of Forest Workers and Harvesters and the Labor Occupational Health Program, U.C. Berkeley; 2011. https://www.osha.gov/sites/default/files/2018-11/fy10_sh-20823-10_chainsawsafety-eng.pdf.

- United States of Department of Labor. 1910.266 – Logging operations. occupational safety and health standards. Washington (DC): Occupational Safety and Health Administration; [accessed 2021 Feb 12]. https://www.osha.gov/laws-regs/regulations/standardnumber/1910/1910.266.

- United States of Department of Labor. Regulation (standards – CFR) 1910 Subpart I – personal protective equipment. Washington (DC): ; [accessed 2021 Mar 12]. https://www.osha.gov/laws-regs/regulations/standardnumber/1910.

- Schnittschutz. Ablauf Schnittschutzhosentest. 2015 [accessed 2021 Mar 12]. https://www.youtube.com/watch?v=3e41y-aUljA.

- STIHL. Pro markTM apron chaps – 9 layer: specifications. Waiblingen, Germany: Stihl; [accessed 2021 Jun 12]. https://www.stihlusa.com/products/protective-and-work-wear/chain-saw-protective-apparel/aprnchap/.