Backpack sprayers are an economical and efficient method for forest landowners to treat unwanted vegetation in and around their woodlands. They can be used to control invasive species, herbaceous vegetation, and woody shrubs and trees, prepare areas to be raked for pine straw, and release young pine seedlings from the competition. Non-commercial grade sprayers can usually be purchased at farm and garden supply stores, home improvement centers, or online for less than $100. Properly calibrating the sprayer prior to use is necessary to ensure that an herbicide is applied at the rate recommended on the label, which is a legally enforceable document.1 This will provide adequate control of the target species, limit damage to non-target species, reduce product waste, and prevent misapplication of active ingredients. Calibration is particularly important when applying active ingredients that have a narrow margin between rates per acre that are effective and those that can have residual negative site impacts. This publication will detail three methods for backpack sprayer calibration. These are the area method and 128th-acre method for herbaceous vegetation application, and the spot method for the treatment of vines, shrubs, small trees, and vegetation growing in dense clumps or vertically.

Preparing for Calibration

Before calibrating, measurements are required to calculate the application rate of the selected sprayer and nozzle. Equipment needed for the measurements includes a container graduated in ounces, a measuring tape, and pin flags or spray paint. A stopwatch or the stopwatch feature on a smartphone will also be needed. Although backpack sprayer calibration is usually done with water and not the product which will be applied, it is recommended to wear all of the personal protective equipment (PPE) required on the product label during calibration. This will ensure that the actual application rate does not differ from the calibration rate due to the addition of PPE, such as heavier boots (that may slow down walking speed or movement through dense vegetation), rubber gloves (which may alter finger pressure on the sprayer trigger), or eye protection (which may restrict vision).

Inspect the sprayer to make sure all fittings are tight, hoses are intact, and that the pump is working properly. To make the calibration results more accurate for the area method and 128th-acre method, practice walking at a steady pace with the backpack sprayer full. Also, since most non-industrial sprayers do not come with a pressure gauge, maintaining a consistent rate of pumping to provide a steady flow rate from the nozzle should be practiced.2 Spray width will vary with the height of the nozzle above the ground. Therefore, a weighted cord or chain should be tied at the end of the wand near the nozzle to maintain a set spray height above the ground surface when calibrating for a foliar application. The calibration steps for all three methods should be done at least twice to provide the most accurate application rates.3

Methods for Calibration

Area Method

Step 1. Measure and mark a 1,000 ft2 area (20 feet wide by 50 feet long) using pin flags or spray paint.

Step 2. Add a known quantity of water to the backpack sprayer tank. The addition of a horticultural dye can be made in the tank if the contrast between sprayed and unsprayed areas will be difficult to determine visually.

Step 3. Spray the marked area using a steady walking pace and consistent flow rate with the nozzle a set height above the ground.

Step 4. Measure the volume of water remaining in the tank. The difference between this volume and the volume in Step 1 is the volume sprayed per 1,000 ft2. When calibrating, if measured volume before and after spraying was determined in units other than those on the product label, the necessary conversion to the labeled unit must be made.

Step 5. To calculate the application rate in gallons per acre (gpa), multiply measured volumes in gallons by 43.56.

Alternative Area Method: Record the amount of time that it takes to spray the marked 1,000 ft2 area following guidelines in Step 3. Then using the container graduated in ounces, capture the spray from the nozzle in the same amount of time taken to spray the marked area. This will provide the volume sprayed in ounces per 1,000 ft2 and will require conversion to gallons.

128th Acre Method

Figure 2. Spray width can easily be seen and measured on a concrete pad. Image credit: Janet Steele, Clemson University.

Step 1. Maintaining a consistent nozzle height, spray a swath on a surface such as concrete where the spray width can easily be seen (figure 2).

Step 2. Measure the width of the swath in inches.

Step 3. Determine the distance that will need to be sprayed to establish a 128th-acre area using the formula: Spray Distance (feet) = 4,084 ÷ Spray Width (inches).

Step 4. Mark the determined distance using pin flags or spray paint.

Step 5. Record the time that it takes to spray the marked area using a steady walking pace and consistent flow rate with the nozzle a set height above the ground.

Step 6. Using the container graduated in ounces, capture the spray from the nozzle in the same amount of time taken to spray the marked area. Gallons per acre (gpa) equals the number of ounces collected in this step.

Spot Method

Typical treatment of invasive or other undesirable species in forested settings often targets individual stems, clumps of vegetation that cannot be walked through at a steady pace, or vegetation growing vertically. These scenarios all require remaining still for a period of time until an application of the herbicide to all foliage in an area is complete before moving to the next section of vegetation to treat. Therefore, the steps to properly calibrate a sprayer for these application methods are done to estimate the volume of the mixture used to effectively cover a known area of the target vegetation.4

Step 1. Select an area of vegetation of similar horizontal and vertical structures with typical leaf surface area of the target vegetation.

Figure 3. Example of the area to use for calibration of backpack sprayer for spot application. Image credit: Janet Steele, Clemson University.

Step 2. Establish a 340 ft2 calibration area by first measuring the height of the test vegetation of the calibration area. For example, the sparkleberry in the longleaf pine stand in figure 3 averages 4 feet in height. 340 ft2 ÷ 4 ft = 85-foot-long calibration area.

Step 3. Mark the determined distance using flagging, pin flags, or spray paint.

Step 4. Add a known quantity of water in ounces to the backpack sprayer tank. The addition of a horticultural dye can be made in the tank if the contrast between sprayed and unsprayed areas will be difficult to determine visually.

Step 5. Spray the vegetation in the calibration area to the same extent of coverage planned for the target vegetation.

Step 6. Measure the volume of water remaining in the tank. The difference between this volume and the volume in Step 4 is the volume sprayed per 340 ft.2 Since 340 ft2 is 1/128th of 1 acre, the volume sprayed on the calibration area in ounces is easily converted at 1:1 to gallons per acre (gpa).

Adjusting to Labeled Application Rate

After completing all of the steps for any of the methods of calibration, it is often necessary to make adjustments to the sprayer to ensure the proper application rate of the chemical to be used. The calibrated rate should be within 5% of the desired treatment rate.2 Adjusting application rate by altering walking speed is often difficult to do since it requires maintaining a pace that may be faster or slower than is comfortable and takes practice to be successful.2, 5 The most effective method to adjust calibration is to either adjust the pressure of the spray or select a different nozzle.

Since most non-industrial backpack sprayers do not have a pressure gauge, adjusting the spray pressure will have to be done by the rate at which the backpack sprayer is pumped. Decreasing the pressure in the tank will lower the rate at which the application is made, and increasing the pressure will increase the application rate.2 Additionally, gauges can be purchased to add to certain brand sprayers to provide the most accurate pressure during spraying.

Figure 4. Fan nozzles (left), and adjustable cone nozzle (right) are commonly included with non-industrial backpack sprayers. Image credit: Janet Steele, Clemson University.

Nozzle selection can also be used to adjust the application rate.5 Most backpack sprayers will come with a basic set of nozzles (figure 4). These are usually labeled generically as high volume (red nozzle) or low volume (yellow nozzle) fan nozzles. Generally, a fan nozzle will be used for many foliar applications, while an adjustable cone nozzle (right in figure 4) is used for spot or directed spraying. Some backpack sprayer wands can be fitted with other brand nozzles that provide more accurate application rates by providing specific spray patterns, flow rates, spray angles, and droplet sizes (figure 5 and table 1) than those that are included with the sprayer.6 Specific nozzle selection should be based on several factors. Most importantly will be the recommendation from the herbicide product label for the application method (foliar, basal bark, cut-stump, or hack-and-squirt), the nozzle type or characteristic to produce the desired droplet size most effective for the various application methods, and maximum and minimum effective active ingredient volume per acre.5, 6 Other factors will include the anticipated wind direction and speed on the day of application, the species of vegetation to be sprayed, and desired spray pattern. Individual nozzle descriptions and recommendations for application purposes are available on manufacturer and retailer websites.5

Figure 5. TeeJet® is one brand that manufactures a wide variety of nozzles that provide more accurate delivery rates. The nozzle spray angle is indicated by the first two numbers (80=80 degrees). Nozzle colors vary to indicate flow rate in gallons per minute (GPM) based on 40 psi, which is also represented numerically by the last two numbers. Yellow nozzles provide 0.20 GPM (02), blue nozzles are 0.30 GPM (03), red are 0.40 GPM (04), and brown are 0.50 GPM (05). Other nozzle markings will indicate specific features such as extended range (XR) or drift guard (DG) and the nozzle material (S=stainless). Image credit: Justin Ballew, Clemson University.

Table 1. Common nozzle types used for forestry applications manufactured by TeeJet®.

| Nozzle Type | Application | Benefit/Common Uses | Common Spray Angle | Desired Spray Quality (Droplet Size) |

| Even flat fan | Band Spraying | Even Spray Pattern | 80 | Fine, Medium |

| Flat fan | Broadcast Spraying | Wide Coverage Area | 110 | Fine, Medium, Coarse |

| Twin flat fan | Broadcast Spraying | Coverage of dense vegetation | 110 with 60 between spray patterns | Medium, Coarse, Very Coarse |

| Hollow Cone | Spot/Directed Spray | Defoliants, fertilizers, fungicides, insecticides; low rates of AI/acre | 80 | Fine, Very Fine |

| Full Cone | Spot/Directed Spray | Basal bark; high rates of AI/acre; soil-applied herbicides | Applicator adjusts – recommended 30 to 45 from vertical | Coarse, Very Coarse |

| Adjustable | Multiple | Adjustable from cone spray to stream | Variable | Fine, Medium, Coarse |

Finer spray droplet sizes are more prone to drift but provide better coverage for most leaf surfaces since increasing droplet size increases the impact of the droplet on the leaf surface, resulting in runoff.5 The same nozzle will produce more coarse droplets under lower pressure spraying and more fine droplets under higher pressure spraying. Spray pattern and penetration into target vegetation can be altered by adjusting the nozzle spray angle, with wider spray angles creating finer droplets.6 Spray patterns can be altered by using dual nozzles on the end of the wand or by adding drift guards or cones. Wand extensions are available to increase the effective spray height during applications. Any adjustments that are made to either spray pressure or changes to a different nozzle require that all of the calibration steps be repeated. Also, the calibration steps are for the individual applicator, not just the equipment. Any time someone else will be making a chemical application using the same backpack sprayer, the calibration steps need to be repeated.4

Mixing and Applying Chemicals

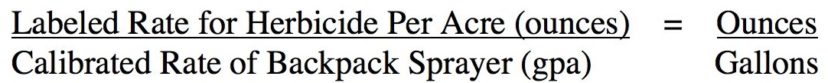

The rates for most herbicides labeled for forestry use are usually given as a percent of the active ingredient in solution or as a recommended application rate of active ingredient per acre with instructions on how to mix. Resources are available that provide formulas and tables to assist with calculating the volume of active ingredient for specific application rates per acre.3, 7 However, calibration steps may result in gallons per acre (gpa) spray rates which are not listed in a table. The following formula can be used to assist with calculating the volume of liquid active ingredient that should be utilized for the labeled rate4:

Example: Forestry Garlon4® is recommended at the rate of 1 to 8 quarts per acre to treat broadleaf weeds mixed in enough water to apply a minimum of 5 gallons per acre.8 Using a moderate rate of 4 quarts of active ingredient per acre, convert the labeled rate to ounces (4 quarts/acre x 32 ounces/quart = 128 ounces/acre). If a calibration method resulted in the backpack sprayer applying 15 gpa, then the volume of Forestry Garlon4® to use is:

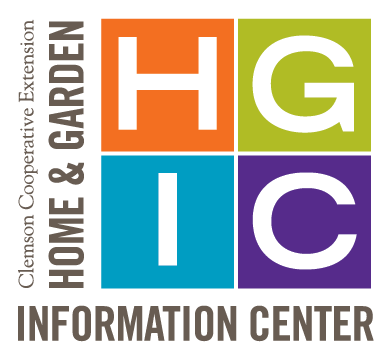

Figure 6. Appropriate Personal Protective Equipment (PPE) during the use of a backpack sprayer for herbicide application. Photo Credit: James H. Miller, USDA Forest Service, Bugwood.org.

Liquid and dry formulations are common for forestry herbicides. Similar calculations using dry formulations would be made except the active ingredient rate would be in weight instead of liquid measurement. Product labels will include directions about the order to mix the active ingredient into the tank with other adjuvants and chemicals. The label will also list any chemicals that should not be mixed with the active ingredient.

All label instructions should be followed with each application, including required PPE, time of day, month or season for optimum application, identification of target and non-target species, and maximum application rate. PPE should be worn during mixing, as well as during product application. This usually includes long-sleeves, long pants, shoes and socks, eye protection, and chemical-resistant gloves (figure 6). Safely storing unused herbicides and accurately documenting the herbicide applied, the application rate, and the date of the application are also important steps in herbicide use. This will ensure that herbicides will not be overapplied within a set period and that landowners enrolled in forest certification programs are meeting all required standards for product handling and record keeping. Always remember, the label is the law!

References Cited

- Introduction to Pesticide Labels. Washington (DC): United States Environmental Protection Agency (US EPA); 2017 May 24 [accessed 2020 Mar 31]. https://www.epa.gov/pesticide-labels/introduction-pesticide-labels.

- Roberson G. Calibrating a backpack sprayer. Raleigh (NC); NC State Extension; 2000 [accessed 2020 Mar 24]. AG-576. https://content.ces.ncsu.edu/calibrating-a-backpack-sprayer.

- Duncan C. Herbicide sprayer calibration guidelines. TechLine Invasive Plant News. 2019 Jun 1 [accessed 2020 Mar 30].

- Jackson DR, Gover A, Bohn K. Backpack sprayer calibration for woodland applications. University Park (PA): PennState Extension. 2017 Feb 6 [accessed 2020 May 11]. https://extension.psu.edu/backpack-sprayer-calibration-for-woodland-applications.

- Ozkan E. Proper calibration and operation of backpack and hand can sprayers. Columbus (OH): Ohio State University Extension, Ohioline; 2020 Jan 10 [accessed 2020 Mar 24]. FABE-531. https://ohioline.osu.edu/factsheet/fabe-531.

- McCloskey W, Andrade-Sanchez P, Brown L. Nozzles and droplets: what do the colors mean? Tucson (AZ): Arizona Cooperative Extension; 2012 Jun 8 [accessed 2020 May 11].

- https://cals.arizona.edu/crops/cotton/files/ColorsofNozzles_Droplets.pdf.

- Service foresters handbook. Atlanta (GA): USDA Forest Service, Southern Region, State & Private Forestry; 1986.

- Forestry Garlon® 4 Label. 2006 [accessed 2020 May 11]. https://s3-us-west-1.amazonaws.com/agrian-cg-fs1-production/pdfs/Forestry_Garlon_4_Specialty_Herbicide__(D02-100-024)_Label.pdf.